Our Products

VIKING GEAR PUMP

VIKING GEAR PUMP

Worldwide Leader Since 1911 for Positive Displacement Pumping Solutions for Industrial, OEM and Sanitary Applications

Viking ผู้นำนวัตกรรมในอุตสาหกรรมการผลิตปั๊มแบบ Positive Displacement ด้วยการออกแบบ แบบ “Gear-within-Gear” ตั้งแต่ปีค.ศ. 1911 เป็นต้นมา ปัจจุบัน Viking pump เป็นที่รู้จักแพร่หลายในอุตสาหกรรมต่างๆ เช่น Chemical, Petrochemical, Paint, Textile, Plastic / Rasin / Rubber, Oil and Gas, Petroleum Refineries, Lubricating Oil & Grease manufacturing, Animal Food, Chocolate Industry, Pulp & Paper, Machinery Industry, OEM โดยมีตัวแทนมากกว่า 245 ราย กระจายอยุ่ในเกือบ 200 ประเทศทั่วโลก

ด้วยประสบการณ์ด้านการออกแบบและผลิตปั๊มมานานกว่า 90 ปี จึงทำให้ Viking pump มีความเชี่ยวชาญในการออกแบบและผลิตปั๊มให้เหมาะสมและครอบคลุมกับลักษณะการใช้งานด้านต่างๆ ของลูกค้าตั้งแต่..

ผลิตภัณฑ์ต่างๆ ของ Viking pump ประกอบด้วย Internal Gear Pump, External Gear Pump, Rotary Lobe Pump, Rotary Vane Pump, Gerotor, Helical Gear Reducers, Power Load Monitor, Basket Strainers และ Pump System โดยมีขนาดและรุ่นที่เหมาะสมต่อการใช้งานมากกว่า 300 รุ่น เพื่อรองรับทุกการใช้งาน

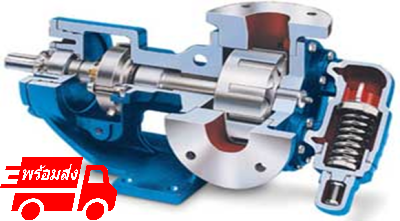

Universal Seal

The Universal Seal series pumps are similar to the Heavy Duty series, offering thrust control and adjustable rotor clearances to compensate for wear and viscosity.

An enlarged bearing housing at the rear of the pump provides easy drive-end access.

Accepts various sealing options including: Packing, Component Mechanical Seals, Cartridge Single-Mechanical Seals Cartridge Double-Mechanical Seals and Cartridge Triple-Lip Seals

Standard-jacketed pumps are typically used for "melting" ambient temperature solids, like asphalt, within the pump prior to startup.

These pumps feature a jacketed bracket and head.

Fully-Jacketed pumps are used in those same applications, plus applications where superior temperature control and faster startup is critical, such as pumping ABS, epoxy and PET resins. These pumps feature jacketed flanges and casing, along with jacketed

Features

Materials of Construction Options : Cast Iron, Ductile Iron, Steel Externals, Stainless Steel

Port size Available : 1.5-8 inch

Specification

High-Speed Compact

The High Speed Compact series pumps are of a Heavy Duty design, with thrust control and micrometer adjustments for accurate rotor positioning.

Designed to operate at motor speeds, they are offered in a close-coupled version for minimum footprint.

Component mechanical seals are standard, along with integral pressure relief valve.

Features

Materials of Construction Options : Cast Iron, Steel Externals, Stainless Steel (foot mount only) Port Size Available : 1-3 inch

Specification

General Purpose

The General Purpose pumps utilize a simple and economical "floating rotor" design, in which the rotor/shaft is not retained by a thrust bearing, and is allowed to "float" within the pump head. This model is well suited to many medium duty applications.

The Asphalt Pump series are economical General Purpose pumps utilizing a "floating" rotor design.

The jacketed head and rotor bearing sleeve are designed to allow passage of saturated steam or heat transfer fluid to melt asphalt that has solidified in the pump prior to startup.

Features

Sealing options include : Packing, Cartridge Lip Seal, Cartridge Single Mechanical Seal, Cartridge Single O-ring Seal, Cartridge Double Mechanical Seal, Cartridge double O-ring Seal

Materials of Construction : Cast Iron

Port Size Available (General Purpose) : 0.25-5 inch

Port Size Available (Asphalt Pump) : 1.5-5 inch

Specification

Mag Drive®

The Viking Mag Drive® series of sealless internal gear pumps eliminate the possibility of shaft leakage by eliminating the seal.

Mag drive pumps are used wherever leakage is a problem, such as acids, volatile organic chemicals, or toxic fluids

Features

Materials of Construction Options : Cast Iron, Steel Externals, Stainless Steel

Port size Available : 1-6 inch

Specification

Abrasive Liquid

The Abrasive Liquid series pumps are designed to maximize pump life handling paints, inks and other abrasive liquids.

With hard materials of construction, these pumps have doubled and tripled the service life of a standard pump

Features

Materials of Construction : Cast Iron (hardening options available for casing and head)

Port Size Available : 0.5-6 inch

Specification

Ammonia

Designed exclusively to handle ammonia and other low vapor pressure fluids in both refrigeration and transfer applications,

these pumps are operated at low speeds to minimize flashing.

They feature double mechanical seals with pressurized seal chamber and oil reservoir to prevent release of gas to atmosphere.

Features

Materials of Construction : Cast Iron

Port Size Available : 1.5-3 inch

Specification

LP Gas

The LP Gas series pumps are designed and UL listed for handling LP gas (propane) or butane for bottle filling, vehicle fueling,

bulk plant transfer and truck-mounted service.

They are built for intermittent transfer services, not for continuous duty or suction pressures above ambient temperature vapor pressures.

All feature mechanical seals and pressure relief valves.

Features

Materials of Construction Options : Cast Iron (sizes FH - HL) Ductile Iron (sizes AS – LL)

Specification

Spur Gear

Viking's Spur Gear series pumps are ideal for low-capacity, high-pressure, motor-speed applications.

All pumps increase by capacities of 40%, so there is always a pump within 20% of your capacity needs.

These pumps offer lips seals, mechanical seals or Mag Drive® options.

Double pumps offer two independent pumping units operated from a single power source to reduce equipment costs.

These may be used to pump from one fluid source to two applications, two fluids to two applications, or for proportioning two fluids together.

Standard pumps do allow some mixing within the pump, but optional seals are available to prevent mixing if needed.

Features

Material of Construction Options : Cast Iron, Ductile Iron (SG-05 and -07 series)

Port Size Available : Single : 0.375 – 1.25x1.5 inch

Double : 0.5-1 inch

Specification

Lid-Ease® Basket Strainers

The Viking Lid-Ease® strainers provide protection for any pumping system by preventing solids or foreign materials from entering the pump.

Port options include grooved, tapped or flanged.

Optional magnetic inserts are available for trapping ferrous particles,

and optional differential pressure indicators are available

for monitoring when the basket needs to be cleaned.

Features

Materials of Construction Options -

Aluminum : 2-4 inch

Cast Iron : 0.75-8 inch

Ductile Iron : 2-6 inch

Stainless Steel : 0.75-6 inch

All baskets are 304 or 316 Stainless Steel.

Maximum temperature on all models is 400oF (204oC).

Specification

VIKING Gear Reducer

Single Reduction Gear Reducer

Design Features : Viking offers three sizes of helical gear reducers to reduce standard driver speeds to match pump (or other driven equipment) requirements.

Adjustment slots on the mounting brackets allow the reducers input (high speed) shaft height to swivel to adapt to a variety of motor frames, while the output (slow speed) shaft height corresponds to typical Viking Pump shaft heights.

Double Reduction Gear Reducer

Design Features : Viking offers ten sizes of in-line, double reduction gear reducers to reduce standard driver speeds to match pump (or other driven equipment) requirements. With the in-line design, the input (high speed) shaft is on the same centerline as the output (slow speed) shaft.

All sizes are available with solid input shaft, and sizes 11 through 60 are available with NEMA C-flange motor mount or IEC flange motor mount on the input side.